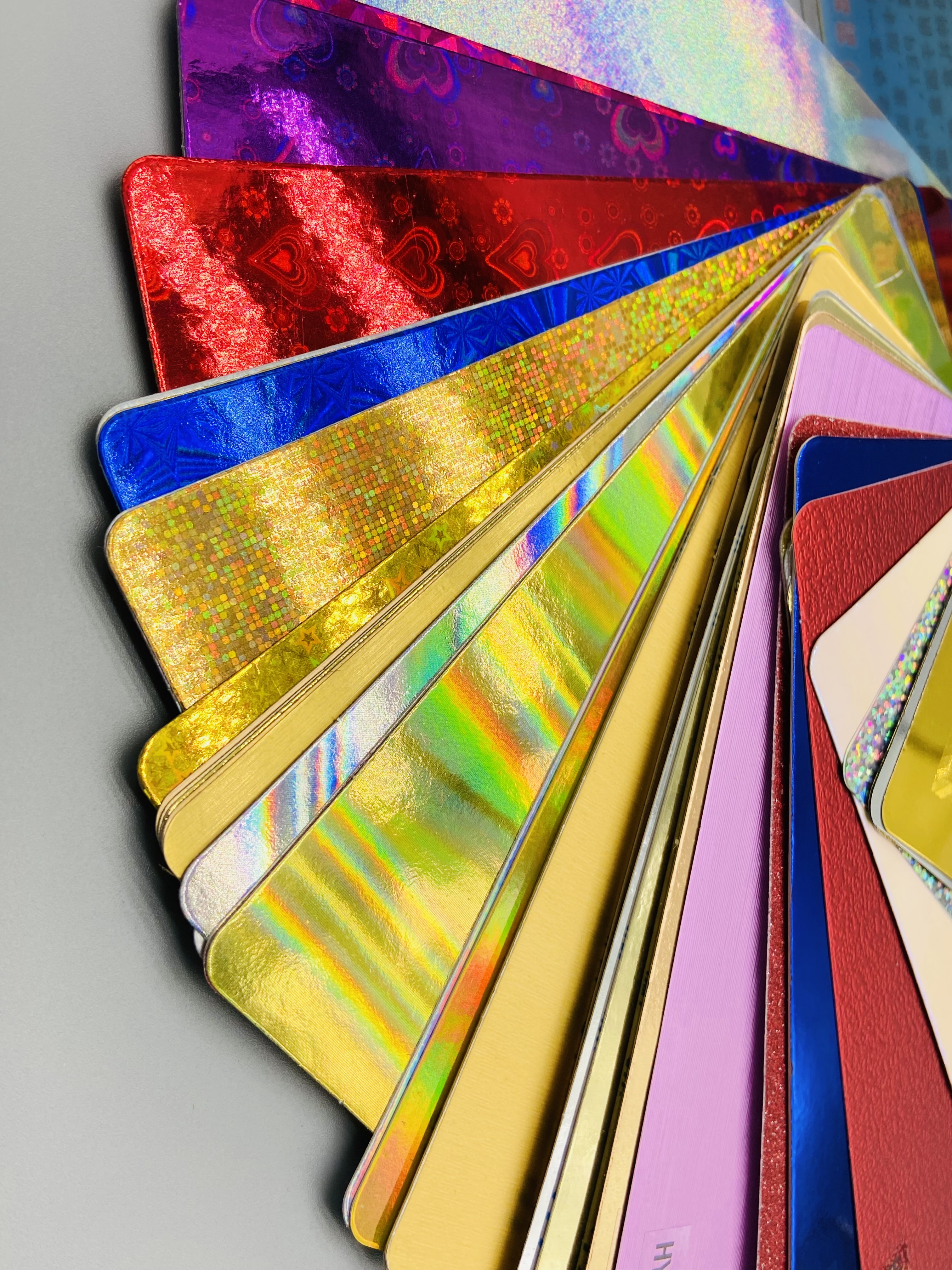

In this article we will introduce some cake board foil --- this material will be used to cover the original material of the cake base, it is not only waterproof and oil proof, but also can beautify the cake board, there are a variety of colors and patterns to choosing , and choosing a cake holder that matches your cake style will make your cake creations look even more appealing.

The material we use now is PET, and we generally use silver, gold, black and white.

PET material is most commonly used in cake substrates, which is very popular and environmentally friendly.

Some of our options are their patterns, and you can even print your LOGO and logo on them. We are the manufacturer and can fully meet any of your custom needs. Generally, the commonly used groups are: grape pattern, maple leaf pattern, Lenny pattern, rose pattern and so on.

How to choose a pattern

There are 4 kinds of patterns we usually use, mainly grape pattern, Lenny pattern, maple leaf pattern and rose pattern.

Recently, there is a new kumquat pattern, which is new and popular.

Regular textures/rounded or geared edges or crimped coils generally don't affect the price.

If the customer wants to put the logo on the cake board, they can choose the copper mold stamp, and the MOQ does not need to be very high.

Plan selection

1. Regular patterns are available: rose pattern, maple leaf pattern, grape pattern, Lenny pattern, kumquat pattern and no texture

2. Customized embossing:

Plan A: Buying a roller, the roller is privately ordered and exclusively used by the customer's personal business, and an agreement can be signed.

Plan B: Engraved steel plate, which is to emboss the exclusive LOGO embossing in the middle of the cake board. The price/performance ratio is relatively high. This program uses more customer choices.

3. It is worth noting that these customization fees are one-time fees and generally will not be refunded.Untextured and textured, the price is almost the same, the price of textured and untextured or pressure ring is the same.

Printing MOQ

At present, the order is based on 3,000 pieces of one size, because the cost of producing samples is relatively high and the process is relatively complicated.

It is also worth noting that we generally use digital printers to produce samples. Digital proofing is because it is cheaper.

The pattern of the sample is not used to check the color, but to check the style of the design, such as whether the pattern or text is correct. Because the shades of the two colors printed by the same digital proofing machine may be different.

It is difficult for digital samples to have the same color for each batch; if the color requirements are really high, you can print spot colors. For printed or light-colored face paper, choose white card

Silver and gold do not need a white card because it can be covered, but a white card can also be added if the customer requests.

If you want to print or light color, it is best to use white card for the face paper, otherwise the surface will be ugly.

How to distinguish between aluminum foil and PET material?

The more intuitive way to distinguish PET and aluminum foil is that PET can see the reflection more clearly, but aluminum foil is not good, and the reflection is not so strong; PET is a kind of plastic, which is thinned by a certain technology and then plated with aluminum. At present, only gold and Silver PET is mostly used for die-cut cake base board;

The aluminum foil is thicker and is generally used as a textured cake board. The non-textured ones are easy to scratch, and are mostly used for edging/surrounding cake trays. The primary color of aluminum foil is silver, if you want to achieve gold or rose gold or other colors, you need to add toner.

Test standard: aluminum depends on the metal content, PET depends on the glue content.

Note: 1. Whether embossing and smooth surface do not affect the price. There are also glossy and matte finishes: most clients will opt for the matte finish, which they feel is more premium. The glossy surface looks blingbling and can sometimes be used as a mirror.

About sample fee

Every time a test sample is produced, it is not so simple to complete. The production workshop master needs half a day to adjust the machine.

Sometimes it takes a long time to run for the material. The time and labor cost is actually more than the sample fee, so you can see the complexity of our sample production process.

If you have doubts about the sample fee, you can ask questions, we can send the process video to the customer to understand, so that the customer can truly feel our efforts for this sample, although it is only a sample, but we are also in Seriously, meticulously pay.

Other

In the article introduced during the factory visit, we will see that the cake board with the surface paper or the bottom paper is pressed with some heavy things, just to prevent the product from being deformed and warped due to the action of glue, pressing it Keep it flat.

After the glue is applied to the face paper or bottom paper, our products are not packaged immediately, but need to be dried in a dehumidifying room to dehumidify. This process takes about 2 days.

This process can well avoid the quality problems caused by the wet and mildew of the glue. Currently we have 4 dehumidification rooms, which is our strength.

In terms of shipping, some of the whole cabinets will be equipped with forklift legs to facilitate loading and unloading.See customer requirements.

The outer packaging of the box can print the information required by the customer. Some customers will ask for bar codes or labels to see the needs of different customers, but we can do all of these, but the price is different.

Related Products

Post time: Mar-26-2022