Cake slice box manufacturing might not seem like a complex task at first glance, but it's a meticulous process involving multiple detailed steps. Each stage of production needs to work in harmony to meet quality standards and delivery deadlines. In this article, we'll take you through the entire process of making cake slice boxes.

Overview of Cake Slice Box Manufacturing Process

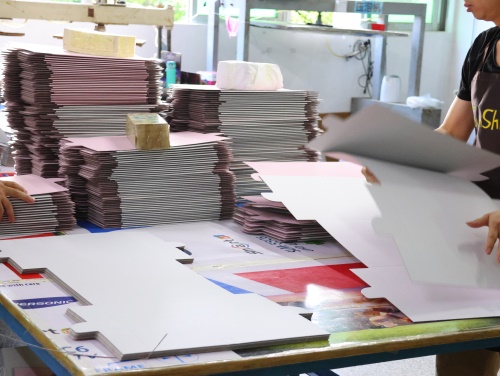

The production of cake slice boxes encompasses a series of interconnected steps. Streamlining these steps is crucial for ensuring the efficient creation of high - quality boxes. The main steps include:

- 1.Design and Template Creation

- 2.Material Selection and Preparation

- 3.Cutting and Forming

- 4.Printing and Decoration

- 5.Assembly

- 6.Quality Inspection and Packaging

1. Design and Template Creation

When you approach us with your ideas for cake slice boxes, our design team gets to work. Cake slice box design isn't just about aesthetics; it also needs to consider functionality, like easy opening and closing, and proper fit for the cake slices. If you have a clear design in mind, our team will translate it into a digital format suitable for production. They'll create a template that precisely defines the shape, size, and structure of the box. For example, if you want a box with a unique fold - out handle or an intricate window design, our designers will work out the technical details. However, if you're not sure where to start, our designers can offer inspiration. They'll show you examples of successful cake slice box designs in the market and help you come up with a concept that aligns with your brand image.

2. Material Selection and Preparation

White Cardboard: A popular choice for its affordability and versatility. It comes in different thicknesses. Thicker cardboard provides more durability, making it ideal for transporting heavier cake slices or for boxes that need to withstand multiple openings and closings.

Kraft paper: Known for its eco - friendly nature. Kraft paper gives the boxes a rustic, natural look, which is perfect for bakeries with an organic or artisanal brand image.

3. Cutting and Forming

4. Printing and Decoration

Offset printing: Ideal for high - volume orders, offset printing provides sharp, vibrant colors. It's perfect for printing detailed logos, patterns, or product information on the boxes.

Digital printing: A more flexible option, digital printing allows for quick turnaround times and the ability to print variable data, like personalized messages or batch numbers.

Embossing and debossing: These techniques add a tactile element to the boxes. Embossing raises the design or text, while debossing creates an indented effect, both of which can enhance the overall look and feel of the box.

5. Assembly

6. Quality Inspection and Packaging

Structural integrity: Ensuring that the boxes are properly assembled and can withstand normal handling without falling apart.

Print quality: Verifying that the printing is clear, the colors are accurate, and there are no smudges or errors.

Size and shape accuracy: Making sure that each box meets the specified dimensions and has the correct shape.

By following these steps, we're able to produce cake slice boxes that are not only functional but also visually appealing, helping you showcase your delicious cake slices and enhance your brand's image. If you want to learn more about our cake slice box manufacturing services or have any questions, feel free to contact us.

Related Products

Post time: Mar-10-2025